Many direct benefits of our thickness measurement equipment include documented compliance with ISO9001 and other quality specifications, increased productivity, improve part quality with verified material thickness, improved process control, and scrap reduction. Our standard system also includes disk storage and easy recall of all coil S.P.C. information. This eliminates your need to maintain large files of printer paper for long-term record keeping purposes.

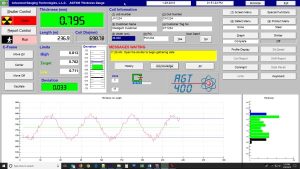

Many people think that gamma isotope gauges are outdated, old technology. But in applications where metals are dirty, oily, covered with scale, or have large passline oscillations the AGT400 isotope gauge will outperform the newer technologies. Our operation and calibration software is so easy and intuitive to use most customers never even open the manual.

Operational Functionality

Features

Our simplified hardware design provides increased system reliability. The measurement system utilizes the latest in technology, to reduce the requirement for peripheral hardware. The system configuration provides a very reliable platform for thickness measurement and S.P.C. reporting.

Our system features fast and accurate method, called ISOcal™. Combined with our AutoComp™ feature, using Alloy specific calibration curves, the result is extremely accurate measurements of a wide variety of material compositions and coatings.

No requirement for air or water. C-frames typically mount on two pedestals but can be adjusted in a variety of ways to fit your needs.

State-of-the-art high-speed electronics and logarithmic linearization assure highly accurate reading of various metals. This translates to consistent and stable thickness measurements.

The system automatically generates several reports, providing all the information you need in user-friendly formats.

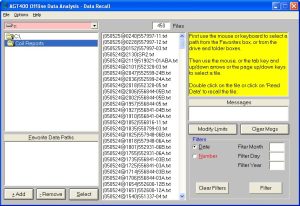

All coil data is automatically stored to your gauges hard drive. Any desired information can be easily and conveniently accessed at any point in the future, and the respective reports reprinted with relative ease.

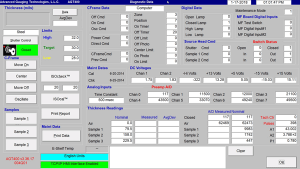

All digital inputs and outputs, analog inputs, and power supplies can be monitored simultaneously in real-time on a single screen. This feature provides for a means of greatly simplified troubleshooting.

Our unique thickness measuring instruments enables future upgrades to be performed in the field in just a matter of minutes.

Calibration

Options

The oscillating c-frame option provides more complete information as it scans the thickness across the width of the sheet instead of just one or two points. The oscillating configuration equips the gauge with additional logic and control circuits enable the gauge to automatically sense the strip edges and scan from one edge to the other. In this configuration, the Profile Display Screen and Reports are enabled, which show a strip cross-section of thickness versus width.

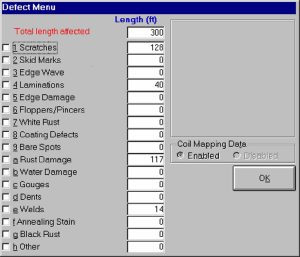

Allows inspectors a convenient method of logging strip defects as they are spotted. Available in single or dual handheld keypad configuration, for one or two-sided inspection lines. Read More

Allows easier access to coil reports by enabling the recall of reports from a single or multiple gauges simultaneously via a company network or USB stick. Reports can be accessed without interrupting the gauge measurement or line operation. Also allows coil reports to be formatted as PDF files.

Includes an additional remote monitor, keyboard, and touchpad mouse.

Standard system includes a 17” LCD flat screen. Optional monitors include a 17” remote flat screen unit, and touchscreen.

To replace the standard system local printer.

Specifications

| Thickness Range | .18 to 6.35 mm (.007 to .250″) steel |

| 2.24 to 10.16 mm (.088 to .400″) aluminum | |

| .13 to 4.19 mm (.005 to .165″) copper, brass, nickel | |

| .48 to 10.16 mm (.019 to .400″) titanium | |

| Air Gap | 2″ – 8″ (7″ nominal) |

| Measurement range | +/- 51 mm (+/- 2.01″) |

| Calibration Accuracy | ± 0.2% or ± 0.0005″ (whichever is greater) over .007″ – .250″ (steel) |

| Precision | .12% @ 3.0 mm thickness, .18% @ 4.6mm thickness, .33% @ 6.4 mm thickness, with 250 ms time constant & 90% confidence |

| Linearity | < .10% over .2 to 6.4 mm thickness range |

| Temperature Range | 0 to 50 deg C (32 to 122 deg F) |

| Humidity Range | 35 to 85% (no condensation) |

| Radiation Source | Am241 – 1 Curie |

| Radiation Detector | Ionization Chamber – 3″ diameter (4″ optional) |