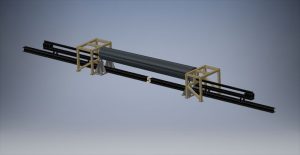

Advanced Gauging Technologies has successfully completed another gauge startup at JMS Russel Metals in Blytheville, Arkansas. Our AGT400 is replacing an outdated GR200 thickness gauge and is installed on a 64″ Stamco Slitter and will measure material up to .250″ thick. This Blytheville plant processes various steel alloys, and with our gauge upgrade JMS can count on the most accurate non-contact thickness measurement available.