Galvasid of Apodaca NL Mexico has purchased a new AGT800 thickness gauge and AGT Width gauge for their new line.

Metals USA buys their first AGT Mult-Width™ gauge

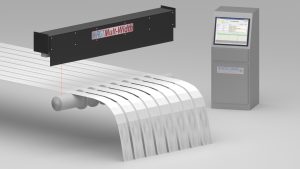

Advanced Gauging Technologies has received the first order from Metals USA in Springfield, OH for the revolutionary AGT Mult-Width™ gauge.

The new gauge will be installed on a 60” Monarch Stamco slitting line. Metals USA is looking forward to more consistent mult width measurements and improved operator safety.

The new AGT Mult-Width™ gauge automatically measures each mult the same way every time. This provides more consistent and accurate measurements while saving time and improving the safety of operators.

After two years of development and testing the new gauge is creating a lot of interest. Look for the article on the February issue of Metal Center News featuring Greenpoint Metals. Sign up for our Webinar to learn more.

#MeasuringMadeEasy

Riverview Steel’s new AGT400

Riverview Steel has purchased a new AGT400 thickness gauge for their new line in Windsor Ont.

Measuring Mult-Widths: Laser vs Camera

Accurate measuring of mult widths on slitting lines has long been a goal of metal processors. Historically, mults (strips cut from master coils) are typically measured by hand which, as most people know, is inconsistent, time consuming and oftentimes unsafe. However, as tolerances become tighter it has become more important than ever for processors to insure that mult widths meet the requirements of their customers.

Fortunately, Advanced Gauging Technologies has answered the call with our new AGT Mult-Width™ Gauging system. This revolutionary new technology uses a laser to provide a more accurate, real-time, non-contact way to measure mult widths.

Our technicians spent a great deal of time testing and evaluating a multitude of measuring options, including commonly used camera vision systems. We ultimately determined that a laser based system was the only way to go. Camera based systems only work when the material being measured is flat, stable and close. There is no room for material movement, up, down or angled, when using a vision system. When the material moves, which is typical on virtually all slitting lines, so does the perceived width of the strip as seen by a camera. We classify this as a “field of view” issue.

Likewise, backlighting which is required for camera systems, can also be a problem. Changes in the amount of light along with dust and scale can all impact measuring accuracy.

The AGT Mult-Width™ gauge overcomes these concerns. As the linear robot moves the laser sensor continuously back and forth across the material, it is able to find the leading and trailing edges of each individual mult and measures the distance between them. This method allows the gauge to operate up to 22” above the material with no loss in measurement accuracy. Additionally, the AGT Mult-Width gauge does not require the use of backlights or reflectors that are subject to changes in light and dust or scale.

Using the AGT Mult-Width gauge will improve accuracy, eliminate set-up errors, provide continuous tracking and recording of mult-widths for documentation, and improve safely and productivity. Please contact Sales@AdvGauging.com for more information and a quote.

Heidtman Steel Orders New AGT400 Upgrade

Heidtman Steel Products, Inc. has ordered a new AGT400 Upgrade for an obsolete GR100 thickness gauge at their Erie, MI plant. The gauge will be located on a 62″ Pro-Eco Slitting Line and used to measure various steel alloys up to .250″ in thickness. This order marks the 10th addition to Heidtman’s family of A.G.T. gauges. We are proud and honored to continue our long-term relationship with Heidtman.

Please visit Advanced Gauging at AdvGauging.com for additional information.

- « Previous Page

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 77

- Next Page »