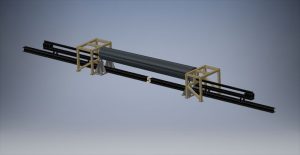

Advanced Gauging Technologies has completed the startup of a new AGT400 at Jemison Metals in Birmingham, Alabama. This system will be used on a 61″ Rowe CTL line to measure various steel alloys up to .250″ thick. With the installation of this gauge Jemison Metals will be able to reduce downtime, improve efficiency, as well as provide the most accurate and reliable non-contact thickness measurement available. Jemison has been a long time customer of A.G.T. and this will be their eighth gauge purchase from us.