Article appears in Metal Center News Magazine, March 2016.

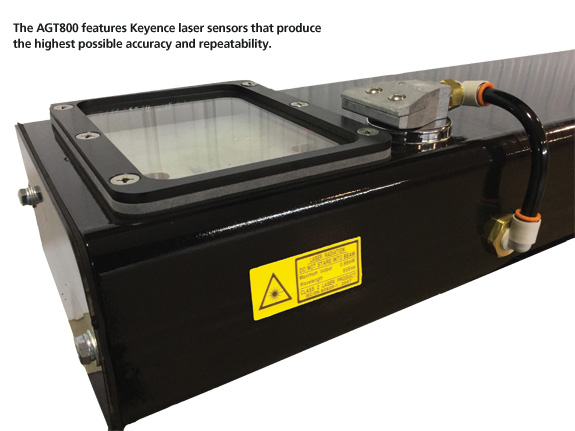

March 2016 – Advanced Gauging Technologies, Plain City, Ohio, offers its patented AGT800 laser thickness gauge, designed to measure any alloy processed in coil, sheet or strip form. The AGT800 is an optical-based measuring system that uses high-precision Keyence laser senors. Each sensor emits a Class II laser beam and receives the beam back on a RS-CMOS pixel array. The gauge then determines the exact distance to the target material and calculates a precise material thickness.

The AGT800 features an intuitive, easy -to-operate user interface making it convenient for operators to access information and navigate between screens, the company claims. It provides graphic representation of strip thickness over the entire length of the coil and dictates out-of-tolerance material instantly. The system is calibrated using N.I.S.T-traceable samples. Detailed S.P.C. reporting and data storage are standard features included with the AGT800.

Direct benefits realized through the measurement process of the AGT800 include documented compliance with ISO9002, QS9000, improved process control, increased productivity and scrap reduction. The standard system also provides disk or network data storage and easy recall of all S.P.C. information. This feature eliminates the need to maintain large collection of printed reports for the long-term record keeping purposes.