WHO IS ADVANCED GAUGING TECHNOLOGIES, L.L.C.?

A.G.T. has been manufacturing and servicing non-contact thickness gauges for over 25 years. To date, we have installed and serviced more non-contact thickness gauges in North American metal service centers than any other gauging company. Located in Plain City, OH, we continue our tradition of developing innovative measurement solutions for a wide range of customers and markets.

A.G.T. has been manufacturing and servicing non-contact thickness gauges for over 25 years. To date, we have installed and serviced more non-contact thickness gauges in North American metal service centers than any other gauging company. Located in Plain City, OH, we continue our tradition of developing innovative measurement solutions for a wide range of customers and markets.

WHAT GAUGING SOLUTIONS DOES A.G.T. CURRENTLY OFFER?

We provide non-contact thickness measurement with complete S.P.C. reporting on both our AGT400 and AGT800 gauges. We also offer a lower-cost option for real-time thickness measurement only with our AGT600. Soon to be introduced new products include strip mult-width measurement and full sheet width measurement gauges.

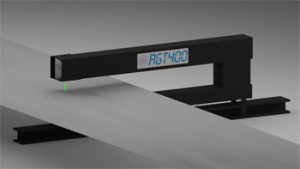

The AGT400 Thickness Isotope Gauge has established itself as the most reliable, user-friendly and accurate isotope gauge on the market and has become the industry standard by which all other isotope gauges are compared.

The AGT400 Thickness Isotope Gauge has established itself as the most reliable, user-friendly and accurate isotope gauge on the market and has become the industry standard by which all other isotope gauges are compared.

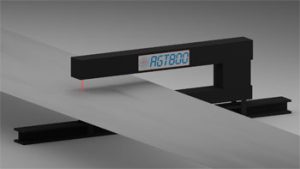

The AGT800 Thickness Laser Gauge uses the latest in laser sensor technology. It is alloy insensitive and can measure any material processed in coil, sheet or strip form with a thickness range of up to .750”. We are the only laser gauge manufacturer to offer Passline Angle Compensation (US Patent #9151595) which compensates for passline angle changes as the material is being processed.

The AGT800 Thickness Laser Gauge uses the latest in laser sensor technology. It is alloy insensitive and can measure any material processed in coil, sheet or strip form with a thickness range of up to .750”. We are the only laser gauge manufacturer to offer Passline Angle Compensation (US Patent #9151595) which compensates for passline angle changes as the material is being processed.

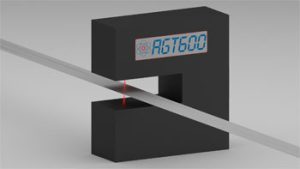

The AGT600 Industrial Thickness Gauge is an ideal replacement for high maintenance contact gauges used in fabricating and mill applications. It includes analog outputs for control feedback, digital outputs for alerts and a simple touch screen control.

The AGT600 Industrial Thickness Gauge is an ideal replacement for high maintenance contact gauges used in fabricating and mill applications. It includes analog outputs for control feedback, digital outputs for alerts and a simple touch screen control.

The AGT600 Lab Thickness Gauge is a compact sample measuring system designed to provide consistent and accurate measurements not attainable with hand calipers.

The AGT Mult-Width™ Gauge counts the number of mults and measures the width of each mult verifying the slitter set up. It will also warn if the sheet has moved off-center by continuously monitoring the outside edges. (Patent Pending)

The AGT Mult-Width™ Gauge counts the number of mults and measures the width of each mult verifying the slitter set up. It will also warn if the sheet has moved off-center by continuously monitoring the outside edges. (Patent Pending)

The AGT Width™ Gauge continuously measures sheet width and edge location on processing lines or mills. It includes data storage, reporting, analog output for steering control feedback and a digital output for out of tolerance warnings.

WHAT SERVICES DOES A.G.T. OFFER?

A.G.T. provides the most reliable and thorough service in the industry. We offer customers unlimited, no charge support via email, phone, fax and the internet. We maintain a regular schedule of semi-annual service visits to ensure our customers gauges are always in top working order and properly calibrated. Our experienced team of field technicians is always available for emergency service when needed.

We also service gauges manufactured by other companies, even obsolete gauges whose manufacturers are no longer in business. We maintain a complete inventory of spare parts for our own gauges along with parts for obsolete gauges than can’t be found anywhere else.

We can upgrade most non-A.G.T. isotope gauges at a cost that is typically around one-half that of a completely new gauge. When upgrading, we are normally able to reuse a customer’s existing C-frame, source and measuring heads. In turn, the customer gets a completely new,state-of-the-art electronics cabinet with all new components and our exclusive AGT400 software and reporting options and features.

In-house repair and refurbishing of damaged or malfunctioning equipment is also available.

WHY SHOULD A.G.T. BE MY MEASUREMENT GAUGE PARTNER?

We have more isotope and laser thickness gauges located in North American metal service centers than all of our competitors combined. Our reputation for quality, accuracy, dependability and service speaks for itself. We offer a wide range of features and options not found on gauges made by other companies. A.G.T. also has several patents including our exclusive Passline Angle Compensation feature (US Patent #9151595) available only on the AGT800.

We provide the best service of any gauge manufacturer, including telephone and email support along with fast turnaround for special service visits. There are no annual contracts for service and we schedule semi-annual visits at pro-rated travel prices whenever possible. We also provide free A.G.T. software updates so you always have the latest features and options at your disposal.

Innovation is a constant at A.G.T. We are always searching for ways to improve our products, service and options for meeting the ongoing needs of our customers. Additional new products on the horizon include the AGT800 Flatness Gauge and AGT800 Pipe and Pole Diameter Gauge.

ARE THERE ANY OTHER SPECIAL FEATURES AVAILABLE ON A.G.T. GAUGES?

Our gauges offer a wide range of features and options that allow users to customize reports to meet their specific needs. Our Next Data feature enables a customer to enter data for the next coil to be run as well as selecting what types of information will be shown (i.e. material supplier, coil or job number, customer P.O. number, etc.). The Product Menu lists all the different alloys a customer will be measuring and uses this information on the AGT400 to ensure accurate measurements no matter what alloy is being processed. Other options include a Shift Summary Report, Automatic Data Entry, Automatic Data Gathering, and the ability to display and print reports in either English or Spanish and data in either imperial or metric units.

All A.G.T. gauges offer fast and easy calibration along with special diagnostic screens which can greatly reduce the time and effort required for troubleshooting should a problem ever arise.