Replace your obsolete contact gauge with the latest non-contact laser thickness measurement technology.

Replacing outdated contact gauges is quick, easy, and can be performed with minimal downtime. The AGT600™ Laser Thickness Gauge is designed to be a direct replacement for your current contact gauges. The C-frame is engineered to fit the existing track and can take advantage of the same motion control, hardware and programing with minimal downtime.

Replacing outdated contact gauges is quick, easy, and can be performed with minimal downtime. The AGT600™ Laser Thickness Gauge is designed to be a direct replacement for your current contact gauges. The C-frame is engineered to fit the existing track and can take advantage of the same motion control, hardware and programing with minimal downtime.

The AGT600™ has dedicated analog outputs for real-time thickness and deviation from target for closed loop process control feedback. The AGT600™ is a non-contact laser thickness gauge and has no sensitive mechanical parts to produce an accurate and repeatable thickness measurement. Maintenance is simply keeping the sensor heads clean and the system calibrated. No more scheduled downtime for the maintenance or replacement of transducers, measurement tips, guide rolls, or suspension components.

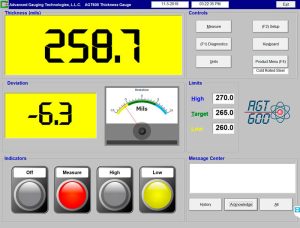

A simple touch screen provides instant thickness and deviation Information. Entered target thickness values and limits will provide digital outputs that can be used for QC lights and a visible indication on the screen. The AGT600 strip thickness gauge measure all kinds of metals, plastics, rubber, vinyl, linoleum and more. It provides fast and reliable thickness measurements using the latest in laser triangulation technology.

A simple touch screen provides instant thickness and deviation Information. Entered target thickness values and limits will provide digital outputs that can be used for QC lights and a visible indication on the screen. The AGT600 strip thickness gauge measure all kinds of metals, plastics, rubber, vinyl, linoleum and more. It provides fast and reliable thickness measurements using the latest in laser triangulation technology.

Contact us today to get an AGT600™ in your plant

Our specifications below reflect real-world accuracy and performance not laboratory conditions specified by some other companies.

Features

Our simplified hardware design combined with Keyence’s ultra high speed, high accuracy laser sensors make the AGT600™ the most reliable laser gauge in the industry.

A.G.T. will design a system to fit your application and installation is as easy as bolting the C-frame into place, mounting the junction box and running the cables through your existing cable carrier. The touch screen interface can be mounted anywhere within 300 feet of the gauge.

The AGT600’s dedicated analog outputs for real-time thickness and deviation from target thickness can be wired into the same machine control inputs used by your current

gauge.

Our system features a fast and accurate calibration method, called ISOcal™ that establishes calibration over a range of samples and reports its calibration accuracy. Our calibration procedure uses N.I.S.T. certified and traceable aluminum samples.

The AGT600™ is a non-contact measurement system, so there is never any risk of our equipment creating marks or scratches on your material.

Gauging your strip at the entry of your roll forming line provides the highest resolution thickness data possible for your profiles.

The AGT600’s compact design is an excellent fit for application or lines where space is limited.

The AGT600™ has a plug and play design. It can be permanently mounted on your line or can be mounted to a mobile stand to be moved from line to line.

Operational Functionality

Options

The N.I.S.T. traceable sample includes a set of six, 6061-T6-651 alloy aluminum — certified and traceable to N.I.S.T. standards.

The custom calibration sample holder includes a black anodized finish.

Specifications

| AGT600™ Compact Laser Thickness Gauge | |

|---|---|

| Material Thickness | 25 µm to 25.3 mm (.001 to .999”) |

| Air Gap | 76 mm (3.0”) |

| Measurement Range | +/- 38 mm (+/- 1.50”) |

| Calibration Accuracy | < 10 µm (0.39 mil) |

| Resolution | < 1 µm (0.4 mil) |

| IEC/IFDA (CDRH) Laser Class | Class 2/Class II |

| Temperature Range | 0 to 50° C (32 to 122° F) |

| Relative Humidity Range | 35 to 85% (no condensation) |